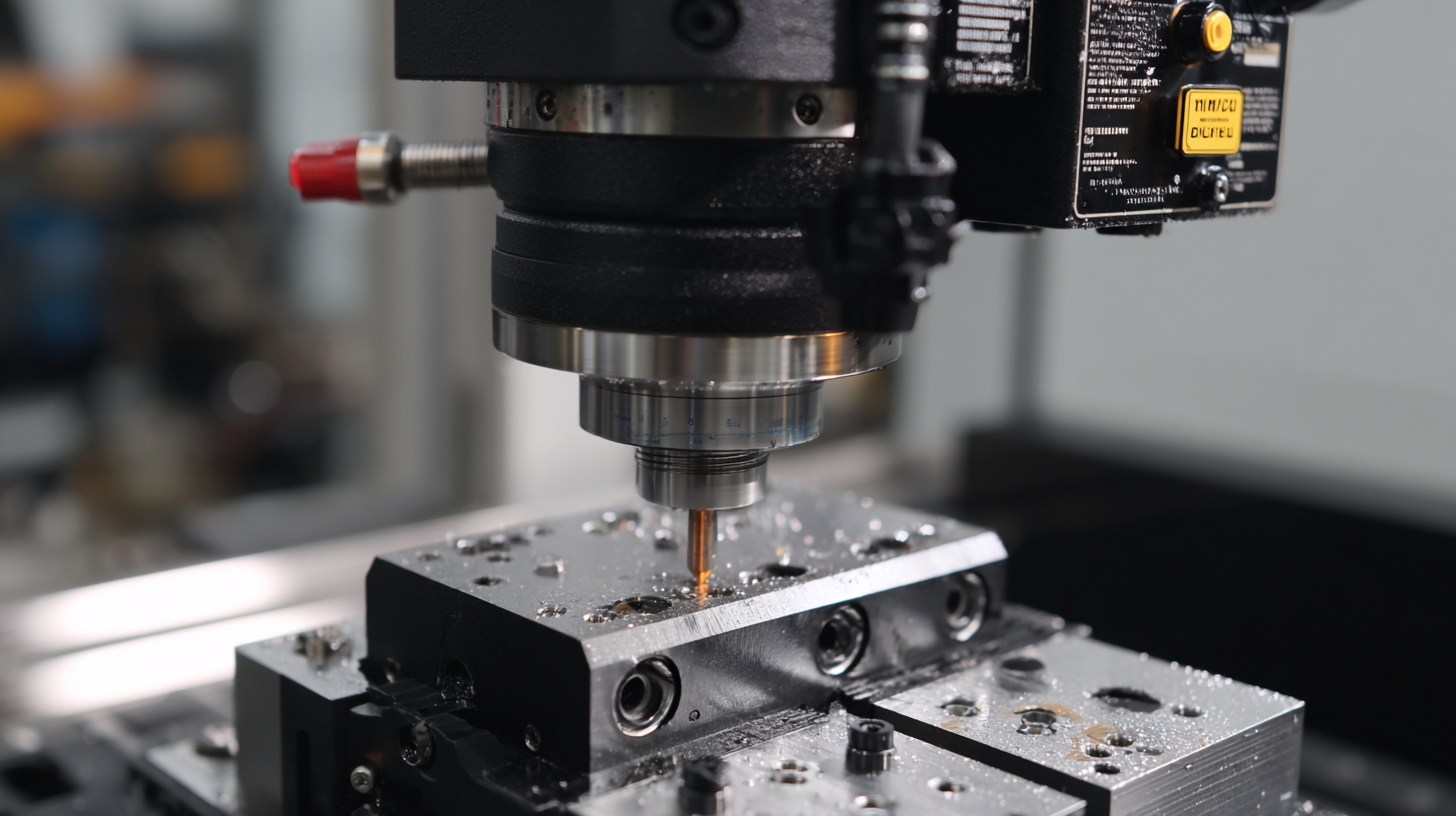

Unlocking Quality Supply: Proven Strategies for Sourcing the Best Desktop CNC Milling Machine Globally

In today's rapidly evolving manufacturing landscape, the demand for precision and efficiency has elevated the significance of the Desktop CNC Milling Machine in both industrial and small-scale applications. According to a recent report from MarketsandMarkets, the global CNC machine tool market is projected to reach $100.92 billion by 2026, with an estimated CAGR of 6.5%. This surge emphasizes the growing reliance on sophisticated milling technologies that can enhance productivity while minimizing waste.

As industries seek to optimize their production capabilities, understanding the detailed technical specifications and top-rated models of Desktop CNC Milling Machines becomes paramount. This blog aims to unlock quality supply and present proven strategies for sourcing the best machines globally, ensuring businesses can harness the full potential of these advanced tools in their operations.

Emerging Technologies Shaping the Future of CNC Milling Machines by 2025

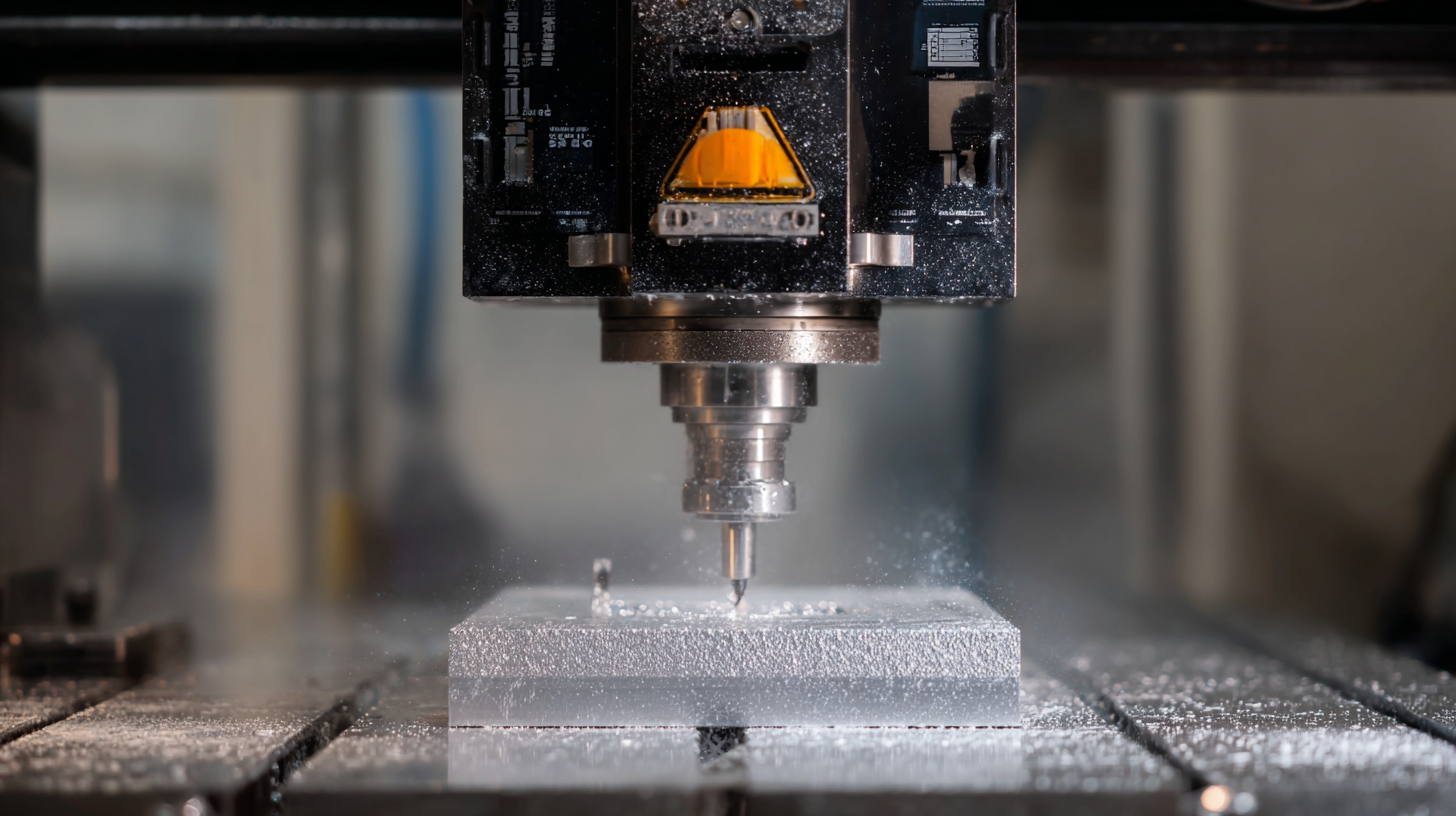

As we approach 2025, the landscape of CNC milling machines is transforming with the introduction of emerging technologies that promise to enhance efficiency and precision. One of the most significant advancements is the integration of artificial intelligence (AI) into CNC systems. This technology enables machines to learn from previous operations, optimize settings automatically, and predict maintenance needs, ultimately reducing downtime and increasing productivity.

Moreover, additive manufacturing techniques are gradually being incorporated into traditional CNC milling processes. By combining these two methods, manufacturers can achieve complex geometries and reduce material waste, leading to more sustainable production practices. Additionally, advancements in materials science are expanding the range of materials that can be effectively machined, making it possible to create more durable and high-performance components. This convergence of technologies not only redefines operational capabilities but also sets the stage for innovative applications across various industries, including aerospace, automotive, and medical sectors. As we look ahead, staying informed about these trends will be crucial for businesses aiming to leverage the best in desktop CNC milling technology.

Key Market Trends: Growth Forecasts and Demand Insights for Desktop CNC Milling

The global market for CNC machines is on a robust growth trajectory, with projections indicating a rise from $101.22 billion in 2025 to $195.59 billion by 2032. This expansion translates to a compound annual growth rate (CAGR) of 9.9%, reflecting a strong demand for advanced machining capabilities. A key driver behind this growth is the increasing adoption of high-precision machining technologies across various industries. As manufacturers seek to enhance productivity and ensure quality, the demand for versatile and efficient desktop CNC milling machines has surged.

In the U.S. specifically, the CNC machines market is expected to achieve significant milestones, projected to reach approximately $4,009.59 million by 2030. This growth is further supported by trends in automation and artificial intelligence, which are transforming traditional manufacturing processes. As the landscape evolves, CNC controllers are also witnessing a substantial increase, anticipated to grow at an annual rate of 8.3% and reach $7.2 billion by 2033. These insights offer a promising outlook for businesses looking to invest in the future of CNC machining, underscoring the necessity of tapping into global supply chains for the best desktop CNC milling machines.

Evaluating Global Suppliers: Criteria and Metrics for Quality Assurance in CNC Equipment

When sourcing a desktop CNC milling machine, evaluating global suppliers is crucial to ensuring quality and reliability. The first step in this process involves identifying key criteria that align with your operational needs. Factors such as production capacity, technological capabilities, and adherence to international quality standards provide a foundational basis for selecting potential suppliers. These criteria not only help gauge the supplier's ability to meet your immediate requirements but also reflect their long-term viability in delivering consistent support and service.

Metrics play a significant role in assessing suppliers effectively. Key performance indicators (KPIs) such as on-time delivery rates, defect rates, and customer satisfaction scores can offer valuable insights into a supplier's operational excellence. Additionally, conducting thorough audits and reviews of previous projects can highlight a supplier's track record and overall reliability. By diligently evaluating these criteria and metrics, businesses can build a robust network of trustworthy suppliers that ensure the acquisition of high-quality CNC milling machines tailored to their production demands.

Cost-Benefit Analysis: Investing in High-Quality CNC Milling Machines for ROI Optimization

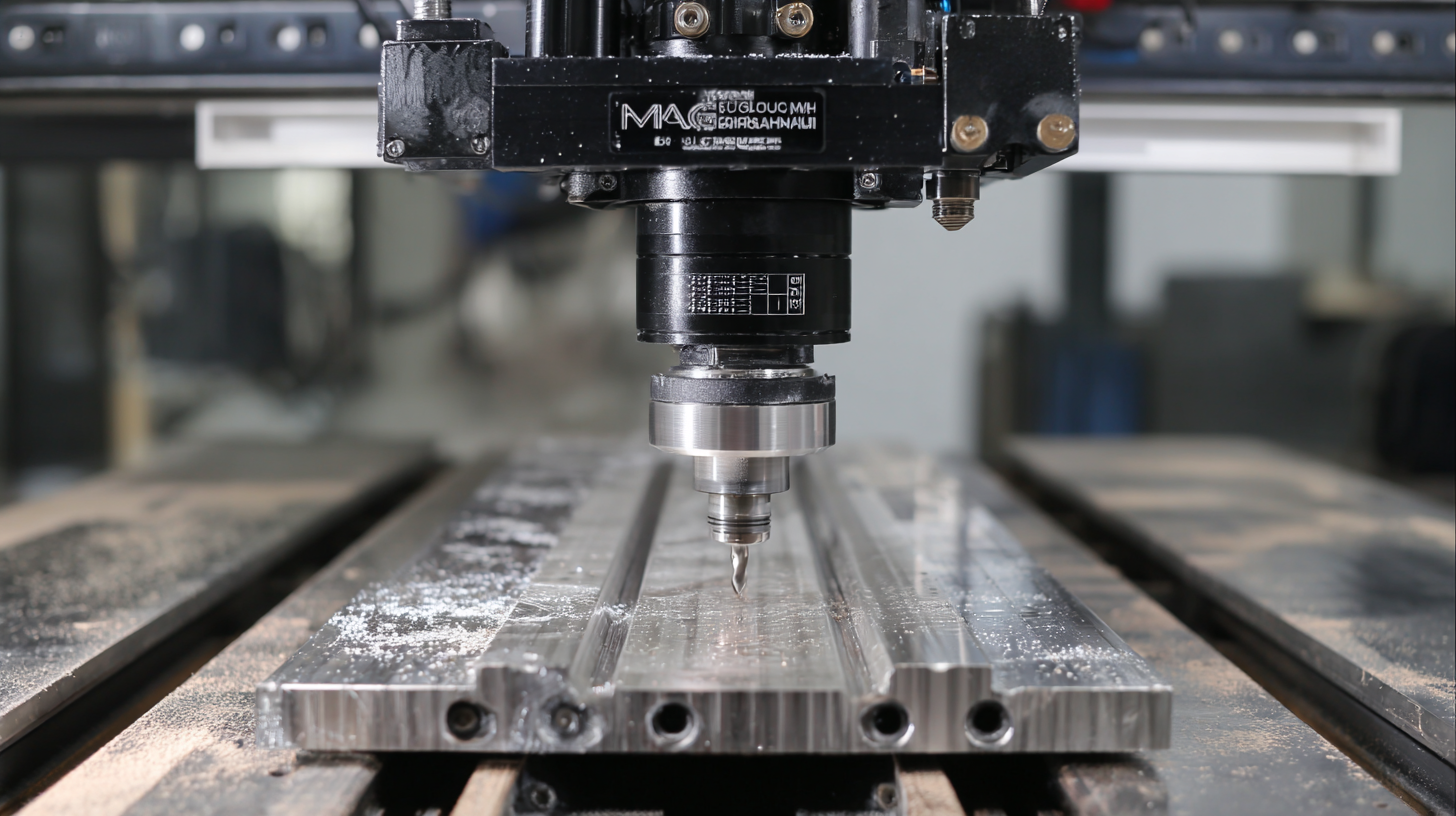

Investing in a high-quality CNC milling machine can significantly enhance operational efficiency and productivity, making it a vital consideration for manufacturers. Conducting a cost-benefit analysis reveals that while the initial investment may be higher, the long-term returns often justify the expenditure. High-quality machines typically offer superior precision, durability, and speed, which can result in reduced waste and increased output. These factors play a crucial role in improving the overall return on investment (ROI).

Moreover, sourcing the best desktop CNC milling machines globally involves evaluating not just the price but also the reliability and support provided by manufacturers. Quality CNC machines may come with advanced features that facilitate automation and ease of use, ultimately leading to fewer downtimes and lower maintenance costs. By selecting a machine that aligns with specific production needs, businesses can optimize their processes and achieve substantial cost savings over time. Prioritizing quality over merely seeking budget-friendly options ensures that manufacturers remain competitive in a rapidly evolving market.

Sustainability in Manufacturing: Eco-Friendly Practices in Desktop CNC Milling Solutions

Sustainability in the manufacturing sector is becoming increasingly vital, especially in the context of desktop CNC milling solutions. One of the key areas where eco-friendly practices can make a significant impact is in the selection and use of cutting fluids. Traditional cutting fluids often contain harmful chemicals; however, innovations in this field have led to the development of eco-friendly alternatives that reduce environmental impact and improve workplace safety.

Moreover, the integration of laser-based technologies into CNC milling processes enhances eco-sustainability. These advanced techniques minimize waste by ensuring precision in cuts and reducing energy consumption. With the growing demand for sustainable practices in manufacturing, businesses are adopting these innovations not only to comply with regulations but also to appeal to environmentally conscious consumers. By embracing digital fabrication and eco-friendly materials, companies can lead the way in sustainable manufacturing, forging a path towards more responsible production methods that are both efficient and environmentally friendly.