Elevate Your Manufacturing with China’s Premier Desktop CNC Lathes: A Global Standard

In today's competitive manufacturing landscape, the integration of advanced technology has become essential for companies aiming to optimize their production processes. The global CNC machining market is projected to reach over $100 billion by 2025, with desktop CNC lathes leading the charge due to their precision and flexibility. Notably, organizations that leverage these machines often report a reduction in operational costs by up to 20%, making them a strategic investment for manufacturers. The advantages of superior after-sales service and lower maintenance costs provided by leading Chinese manufacturers further position desktop CNC lathes as a global standard in this evolving industry. By embracing these innovations, businesses not only enhance their operational efficiency but also ensure sustainable growth in the ever-evolving market. Discover how you can elevate your manufacturing processes with desktop CNC lathes and stay ahead of the competition.

Upgrade Your Production Efficiency: The Impact of CNC Lathes on Manufacturing Output

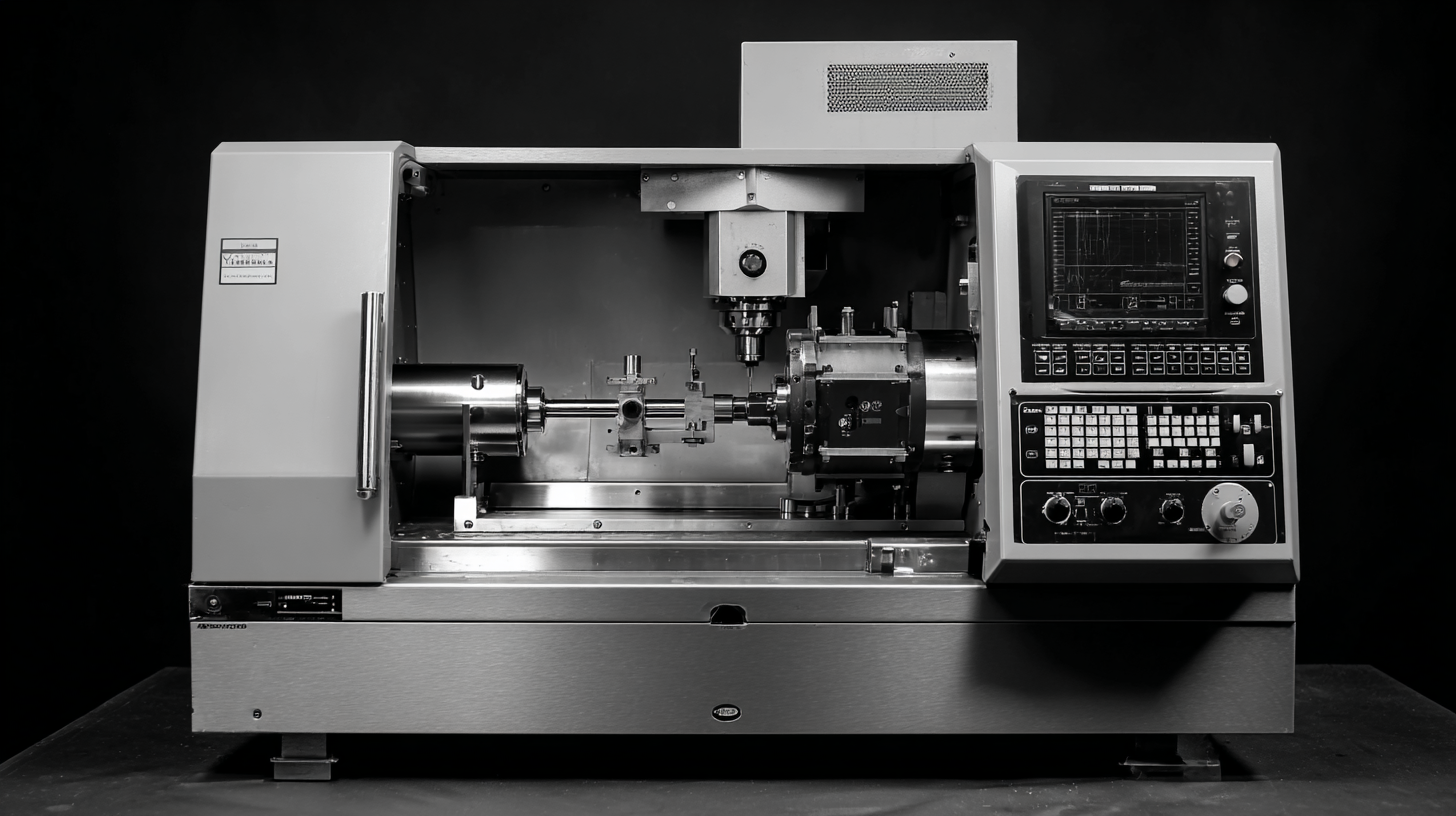

As manufacturing industries strive for greater efficiency, the adoption of Computer Numerical Control (CNC) lathes stands out as a pivotal advancement. These sophisticated machines are revolutionizing production output through unparalleled precision and automation. In a landscape where the global machine tools market is projected to soar from USD 134.96 billion in 2023 to USD 169.47 billion, CNC lathes are at the forefront of this growth, enabling manufacturers to streamline operations and enhance overall productivity.

The impact of CNC technology is particularly pronounced in high-efficiency, high-precision production environments. The rise of advanced CNC features, such as twin-spindle configurations, demonstrates a significant leap in industrial capability. These innovations not only reduce cycle times but also minimize human error, leading to a marked increase in output quality. As systems evolve to embrace Industry 4.0 with effective scheduling and multi-robot task allocation, manufacturers can achieve seamless integration of automated processes, driving efficiency and paving the way for sustainable growth in the sector.

Exploring Cost Savings: How Desktop CNC Lathes Reduce Operational Expenses

As manufacturing industries continually seek cost-effective solutions, desktop CNC lathes have emerged as a game-changer. Recent industry reports indicate that these machines can reduce operational costs by as much as 30% compared to traditional machining methods. This cost efficiency stems from their ability to minimize material waste, streamline workflows, and significantly decrease labor costs through automation. With the increasing precision of CNC technology, manufacturers are also able to produce high-quality parts in shorter timeframes, further enhancing productivity.

Moreover, the compact and versatile nature of desktop CNC lathes allows manufacturers to save on real estate and utility expenses. According to a survey by the Association for Manufacturing Technology, over 60% of manufacturers recognize that investing in advanced machinery like desktop CNC lathes leads to substantial long-term savings. The shift to these modern solutions not only improves the bottom line but also positions companies to be more competitive in the global market. By embracing this technology, manufacturers can achieve operational excellence while maintaining cost efficiency, making desktop CNC lathes a critical investment for future growth.

Elevate Your Manufacturing with China’s Premier Desktop CNC Lathes: A Global Standard - Exploring Cost Savings: How Desktop CNC Lathes Reduce Operational Expenses

| Feature | Traditional Machining Cost | Desktop CNC Lathe Cost | Cost Savings (%) |

|---|---|---|---|

| Initial Investment | $50,000 | $20,000 | 60% |

| Operational Efficiency | 75% | 90% | 20% |

| Material Waste | 10% | 4% | 60% |

| Labor Costs per Hour | $30 | $15 | 50% |

| Maintenance Costs per Year | $5,000 | $1,000 | 80% |

| Production Time (hours) | 100 | 50 | 50% |

Precision and Quality: The Role of CNC Technology in Enhancing Product Standards

The global CNC machine market is set to witness substantial growth, expanding from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, with a projected CAGR of 9.9%. This growth is largely attributed to the increasing demand for precision and quality in manufacturing processes. The integration of CNC technology significantly enhances product standards, ensuring consistency and minimizing production errors. Furthermore, advancements such as Digital Twin technology are revolutionizing CNC manufacturing by optimizing workflows and accelerating production from design to finish.

To maximize the benefits of CNC technology, manufacturers should consider the following tips: First, investing in training for staff on the latest CNC systems can yield higher accuracy and efficiency. Second, leveraging data analytics to monitor machine performance can help identify areas for improvement and streamline production processes. Lastly, adopting AI-driven CNC machines can enhance precision manufacturing, paving the way for innovative solutions and superior product outcomes in an increasingly competitive market.

Market Growth: Analyzing the Rise of CNC Lathes in Global Manufacturing Trends

The global CNC machine market is poised for remarkable growth, with projections estimating an expansion from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. This upward trend in manufacturing is significantly driven by the increasing adoption of advanced technologies, such as CNC lathes that improve precision and efficiency. Notably, the surge in demand for Electrical Discharge Machines (EDM) is anticipated to further enhance this landscape, with the market expected to rise from $6.2 billion in 2022 to approximately $9.4 billion in the coming years.

Additionally, the CNC Cutting Machines market is set to experience a substantial increase, predicted to reach $6,153.2 million, fueled by innovations in cutting tool design and production. This is complemented by robust growth in the CNC Milling Machines sector, which is also on track for significant expansion. The overall CNC machinery market reflects a dynamic shift towards automation and resource-efficient manufacturing processes, making CNC lathes a key component in advancing global manufacturing standards. With the increasing focus on high-quality and cost-effective production methods, the demand for desktop CNC lathes will likely continue to rise, reinforcing their status as a standard in the industry.

User Satisfaction: Customer Insights on Desktop CNC Lathes Versus Traditional Methods

In the ever-evolving landscape of manufacturing, user satisfaction plays a pivotal role in determining the effectiveness of tools and methods. Recent insights reveal that many manufacturers are moving away from traditional machining methods to embrace China’s premier desktop CNC lathes. These advanced machines not only enhance precision and efficiency but also significantly improve user satisfaction. Customers report that the ease of operation and flexibility offered by CNC lathes allow for quicker adjustments and modifications, catering to diverse production needs.

Comparing the feedback on desktop CNC lathes versus traditional methods highlights a stark contrast in user experience. While traditional lathes often require extensive technical skills and time-intensive setups, desktop CNC lathes streamline the entire process. Users appreciate the automated functions that minimize manual labor and reduce the margin of error. Furthermore, the compact design of these machines fits seamlessly into various workshop environments, allowing for greater accessibility and utilization. As manufacturers continue to seek innovations that bolster productivity and quality, the shift toward desktop CNC lathes is a testament to the changing preferences and increased satisfaction among users.