Built on Trust Best Axis Cnc from a Leading Chinese Factory

In recent years, the global CNC market has witnessed significant growth, driven by advancements in technology and increasing demand for precision engineering across various industries. According to a recent report by MarketsandMarkets, the CNC machine market is projected to reach USD 113.39 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.5% from 2021.

As a prominent player in this expanding industry, Axis CNC machines from leading Chinese factories have become synonymous with quality and reliability. These machines not only embody the hallmark of "Made in China" excellence but also showcase the country’s robust export capabilities, characterized by state-of-the-art production techniques and adherence to international standards.

This blog will explore the exceptional quality and trust that Axis CNC machines offer, highlighting why they are recognized as superior representatives of Chinese manufacturing on the global stage.

The Importance of Trust in CNC Machine Purchasing Decisions

When it comes to purchasing CNC machines, trust plays a pivotal role in the decision-making process. Buyers are not merely investing in machinery; they are forming partnerships with suppliers that can impact their operations for years to come. A trusted supplier offers not only high-quality machines but also reliability in service and support. This assurance can significantly enhance a company’s production capabilities and overall efficiency. Thus, trust becomes a critical factor that influences the entire procurement journey, from evaluating options to finalizing purchases.

Moreover, the importance of trust extends beyond initial transactions. In the dynamic landscape of manufacturing, having a dependable CNC machine supplier fosters long-term relationships that benefit both parties. Open communication, transparency, and a proven track record of service can solidify trust, ensuring that customers feel confident in their investments. A leading Chinese factory committed to building trust understands the varying needs of its clients, providing tailored solutions and ongoing support to cultivate lasting partnerships in the CNC market.

Key Features to Look for in High-Quality Axis CNC Machines

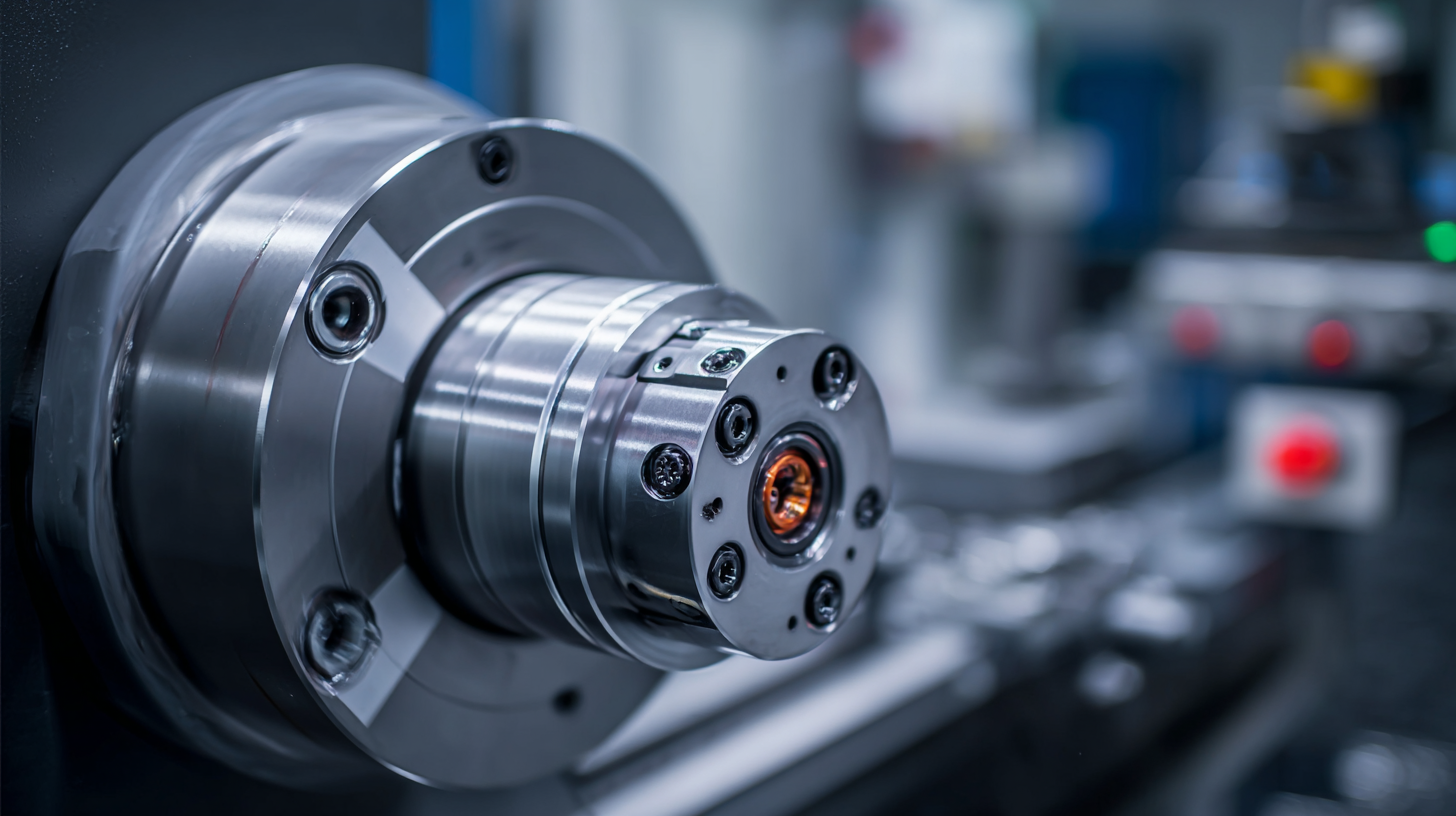

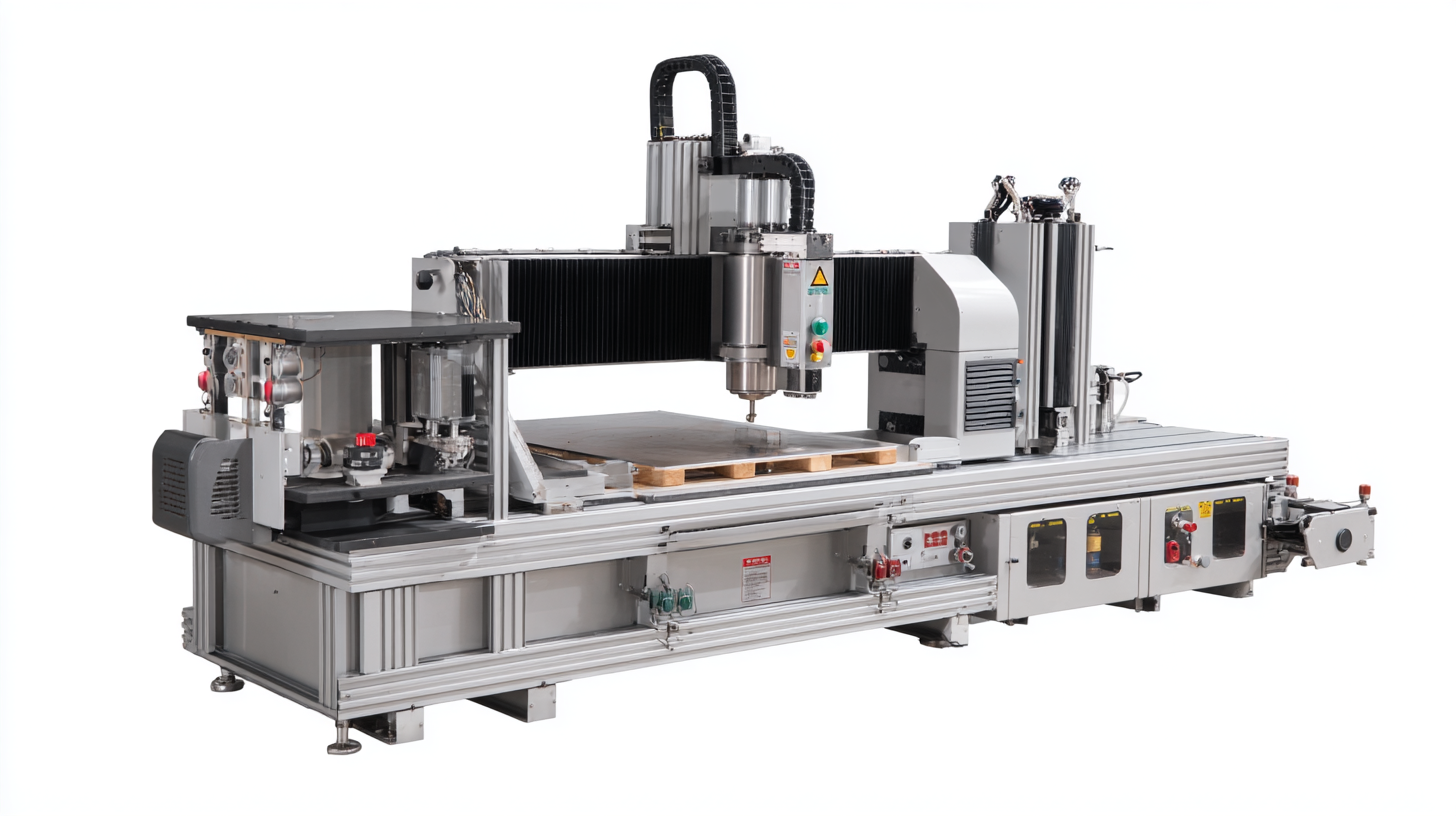

When choosing a high-quality axis CNC machine, there are several key features that should be prioritized to ensure optimal performance and longevity. A report by MarketsandMarkets highlights that the global CNC machine market is expected to grow from $67 billion in 2020 to over $102 billion by 2025, emphasizing the increasing demand for precision manufacturing solutions. One critical feature to consider is the machine's rigidity and stability, as these factors significantly influence cutting precision and tool life. Look for models designed with high-grade materials, such as casting iron or steel, which can absorb vibrations effectively and enhance overall accuracy.

Another essential feature is the machine's control system. Advanced CNC machines often incorporate user-friendly interfaces and sophisticated software that streamline operations. According to a report from Grand View Research, the increasing adoption of IoT-integrated CNC machines is expected to propel the industry forward, offering unparalleled capabilities in automation and remote monitoring. When selecting a machine, prioritizing those equipped with adaptive control technologies can substantially improve efficiency and reduce operating costs.

Tips: Always verify the machine's specifications and reviews before making a purchase. Engaging with industry peers or forums can provide valuable insights into the performance of specific models from reputable manufacturers. Additionally, consider investing in machines that offer customizable options to meet specific production needs, ensuring that you get the most out of your equipment.

Built on Trust Best Axis Cnc from a Leading Chinese Factory - Key Features to Look for in High-Quality Axis CNC Machines

| Feature | Description | Benefits |

|---|---|---|

| High Precision | Maintains tight tolerances for quality output. | Ensures parts fit perfectly, reducing waste. |

| Robust Construction | Built from high-quality materials for durability. | Increases longevity and reduces maintenance costs. |

| User-Friendly Interface | Intuitive controls for easy operation. | Reduces training time and boosts productivity. |

| Versatile Applications | Suitable for various materials and projects. | Enhances flexibility in manufacturing processes. |

| Safety Features | Equipped with multiple safety safeguards. | Protects operators and minimizes accidents. |

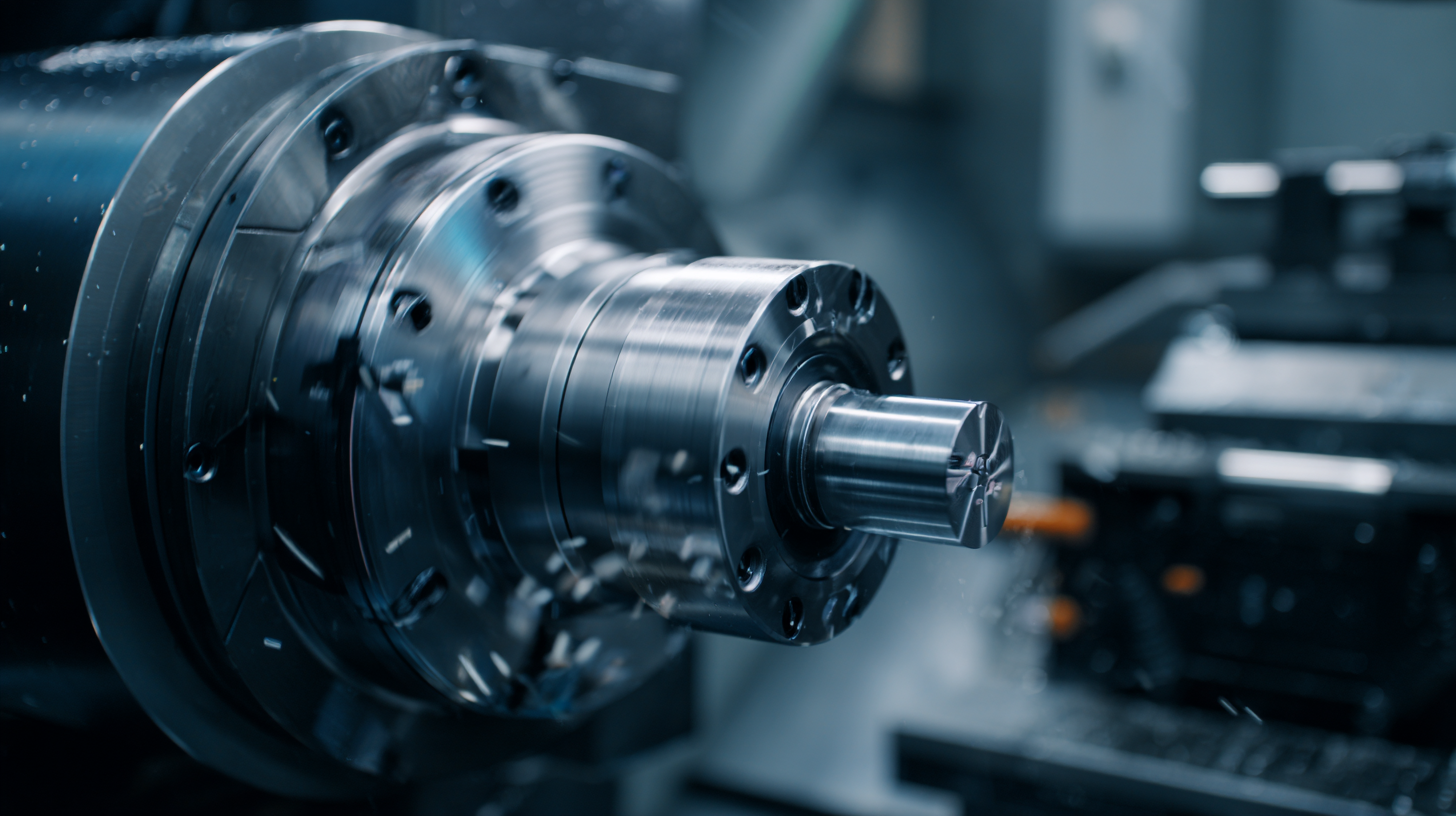

Understanding the Manufacturing Processes of Leading Chinese CNC Factories

The manufacturing processes of leading Chinese CNC factories are intricate and highly specialized, showcasing the country's significant advancements in precision engineering. According to a recent report by Mordor Intelligence, the CNC machine market in China is projected to grow at a CAGR of over 7% from 2021 to 2026, driven by the increasing demand from various sectors, including automotive, aerospace, and electronics. This growth indicates that Chinese manufacturers are not only expanding capacity but are also enhancing their technological capabilities to meet global standards.

One of the primary manufacturing processes utilized by these factories is computer numerical control (CNC) machining, which allows for the automation of complex tasks with remarkable accuracy. Statista notes that the global CNC machining market size was valued at approximately $63.5 billion in 2021 and is expected to expand significantly, with Chinese manufacturers playing a crucial role. They incorporate advanced tooling systems, multimedia simulation, and real-time data analytics to optimize production efficiency. This rigorous approach enables manufacturers to maintain high quality and reliability, ensuring that customers can trust in their products. The commitment to technological innovation and process improvement is what sets leading Chinese CNC factories apart in the competitive landscape.

Analyzing Cost vs. Quality: The ROI of Investing in Trusted CNC Solutions

When it comes to investing in CNC machinery, the balance between cost and quality can significantly impact your return on investment (ROI). Many businesses are tempted to opt for the lowest price, but sacrificing quality often leads to higher long-term costs. Investing in trusted CNC solutions typically offers superior precision, durability, and reliability, which ultimately translates to increased productivity and a better end product.

**Tip 1:** Always consider the long-term implications of your purchasing decisions. A reliable CNC machine from a reputable manufacturer might have a higher upfront cost but can save you money through reduced maintenance and fewer operational disruptions over time.

**Tip 2:** Evaluate the total cost of ownership (TCO). This includes not only the initial investment but also operating costs, maintenance, and the potential for lost productivity due to machine failures. By understanding the TCO, you can make a more informed decision about the best CNC solution for your needs.

Ultimately, a well-considered investment in quality CNC machinery can elevate your manufacturing capabilities and provide a strategic advantage in a competitive market.

Cost vs. Quality Analysis of CNC Machines

This chart illustrates the relationship between the investment cost and the quality rating of CNC machines. The data shows a trend where higher initial investments correlate with better quality ratings based on user reviews and operational efficiency.

Industry Trends in CNC Technology: What to Expect in the Next 5 Years

The landscape of CNC technology is evolving rapidly, and the next five years promise significant advancements. A notable trend is the integration of artificial intelligence (AI) into CNC machining processes, which enhances precision and productivity. As industries seek to optimize their operations, AI's capabilities will likely redefine job roles within the manufacturing sector, creating new opportunities and challenges alike. The CNC machine market is projected to grow at a compound annual growth rate (CAGR) of 5.5%, driven by the demand for more sophisticated and automated machinery.

Moreover, East Asia is emerging as a leading region for industrial robotics, expected to account for over two-thirds of the market share. The surge in robotics and CNC technologies is redefining manufacturing processes, emphasizing smart manufacturing solutions. As companies strive for efficiency, the trend towards 3D printing and additive manufacturing will also gain momentum, with the sector projected to reach a significant valuation by 2030. These developments indicate a transformative period for CNC technology, where innovation and adaptability will be key to success in the industry.